DJmolding’s Products and Services

We’re Low Volume Plastic Injection Molding Expert & Manufacturer

Injection Manufacturing Facility

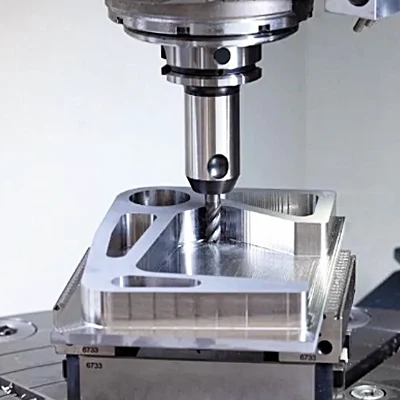

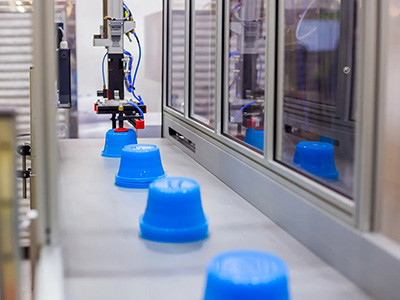

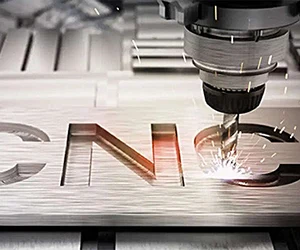

Injection machine x38 range 40Ton to 800Ton equipped with robot daily capacity 1.8 tons plastic parts avrg. Dust-free painting room 2 lines – pad printing, silk printing and UV painting. NC machining (x6) shop for rapid prototype service (plastic and metal) and production of various metal machining parts

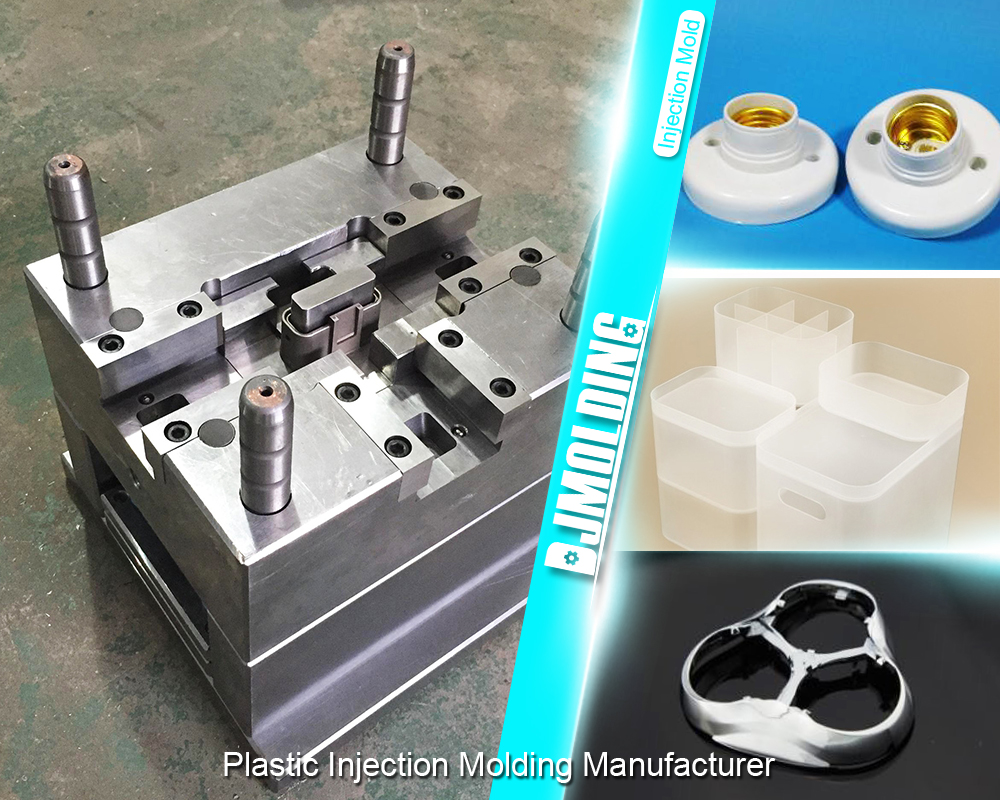

Huizhou Djmolding Co., Ltd (Huizhou Dongjiangjiesong Technology Co., Ltd), established in 2010, is a leading plastic injection moulding and mould manufacturer in China.Djmolding is a professional low volume injection molding,prototype molds maker for plastic parts on demand manufacturing from china. Now we are working as low volume manufacturing service partner with many famous 3D printing and additive manufacturing companies in usa and europe.

Djmolding specializes in plastic mould and plastic parts production for houldhold appliances, medical equipments, electronic equipments, safety equipments as well as monitoring system.

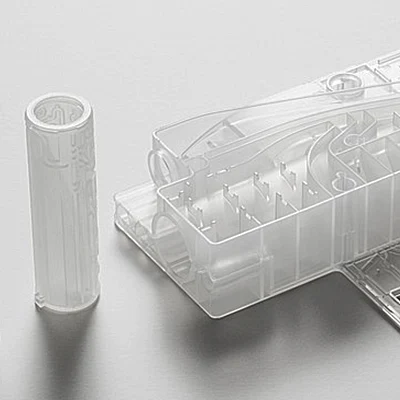

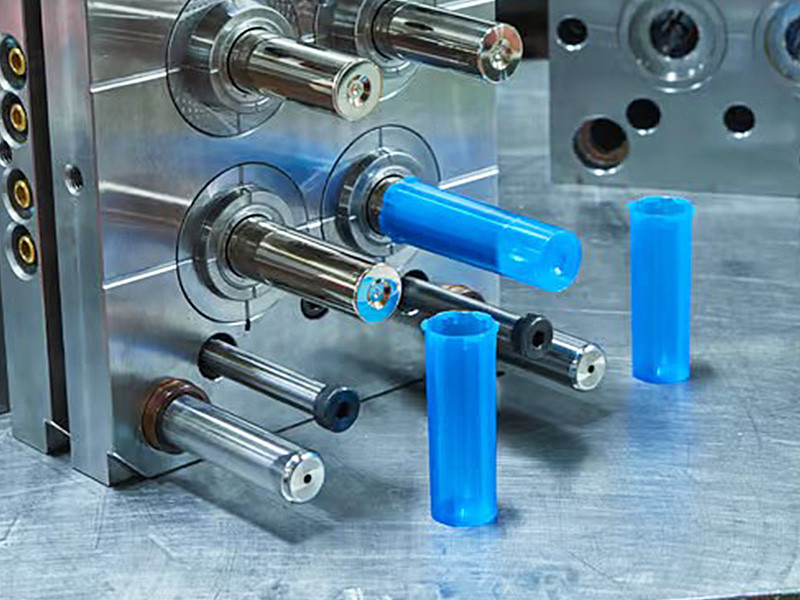

Injection molding, an important manufacturing process at DJmolding. How does it work? The chosen material is liquified and injected into a mold under pressure. In this way, we as a manufacturer can produce prototypes from original material and serial parts up to 50,000 pieces and more.

We have more than 1,000 different plastic materials that we keep in stock. If your plastic component requires a different or special material, you are welcome to provide this material yourself instead of requesting us to procure it. And without any problems whatsoever.

Comprehensive

Fast Tooling & Injection Molding Services

* Add value by increasing efficiency

* Implement automation with fast payoff

* Simplify multi-part tool programs

* Exclusive customer training

* Brings disciplines together for accuracy

* Injection molding technology, materials, tooling, & RFQ process

* Ensures tools are specified correctly

Injection Molding Process

Plastic injection molding is one of the oldest methods of manufacturing plastics and a critical step in the development of parts for product manufacturers. It’s also a great solution for manufacturers looking to convert heavy metal parts to plastic. Explained in its simplest form, the process uses polymers or plastic resins that when heated, melted and injected under high pressure into a custom mold, will produce plastic parts to be utilized in product manufacturing.

While that process seems straightforward, it can actually be quite complex and requires a high level of experience from an injection molder partner that can cater to your unique industry needs, specifications, end-uses and time / budget constraints. The best place to start is by gaining basic knowledge of the plastic molding process and design best practices.

Plastic Injection Molding Which You Can Count On

We can offer customized plastic injection molding end products.

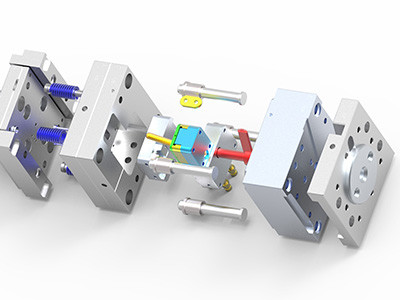

How to make a plastic mould

In today’s manufacturing environment, plastics are used to manufacture a variety of items. Each application requires a special manufacturing process, which can shape parts according to their specifications. If you are making plastic parts, the first thing you need to determine is the type of molding that is best suited to your particular application.At DJmolding, we focus on custom plastic molding.

DJmolding Mould Designing Service

DJmolding design moulds since 2010, that we meet specific customer requirements. DJmolding provides top notch engineering services by combining proven design standards with the most modern techniques available today for designing and manufacturing plastic injection molded parts.

The Best Low Volume Injection Mould Manufacturer in China

We can offer custom plastic injection moulds service.

DJmolding’s Injection Molding Service

We offer the high quality pastic injection services for the global market.

Blogs & News

We’re always focus on the latest plastic injection molding technology and applications.